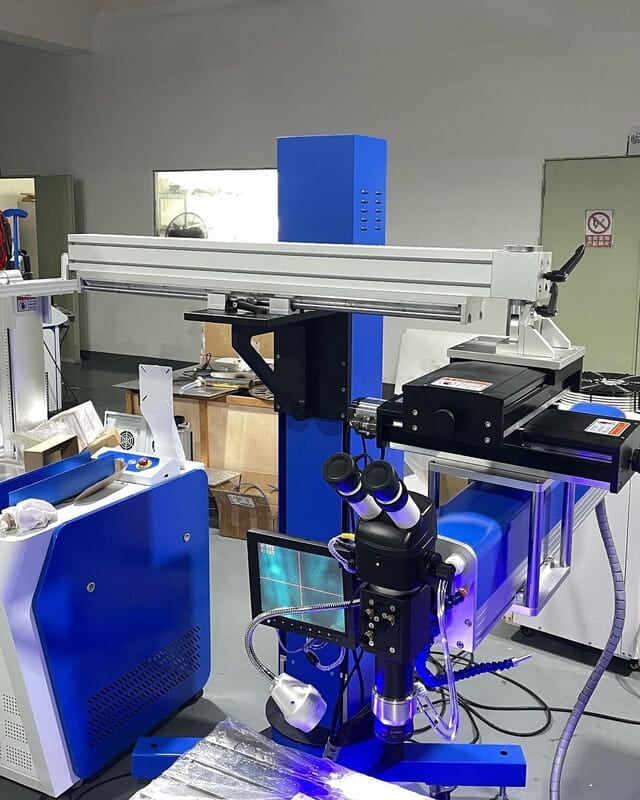

Laser Welding Machine YAG 400W

Unique Features :

Industrial 3-Axis Joysticks.

XY Axis control by Industrial Joysticks, 2-Axis Follow-up Function.

Z-Axis control by Footswitch.

Welding Function Synchronizes with Footswitch.

Double Buttons Welding Functions.

Single Spot Welding & High Frequency Welding Mode.

Choose Quantity

Products Description and Technical Details:

It is specially designed for the mould industry and the technology is imported from Germany. With unique structure design, it is suitable for repairing of large, medium and small moulds.

2.Use the most advanced light shielding system to eliminate the irritation to eyes by light during working.

3.The laser head and optics part can be rotated for 360°, upward/downward lifting and forward/backward pushing, suitable for repairing of large, medium and small moulds.

4.The parameters are controlled by intelligent remote controller, which is simple and convenient.

5.The work bench can be lifted, and moved in three dimensions.

6.The size of light spot can be adjusted.

Technical Specifications :

3-axis stroke of work bench | X=300mm, Y="200mm" (X, Y can be adjusted manually and Z-axis can be lifted) |

Bearing of work bench | ≤200kg |

Device weight | 300kg |

Power supply | 380V ±10%/60Hz |

Laser parameters | Laser parameters |

Laser type | Nd:YAG pulse |

Adjusting range of light spot | 0.1-3.0 mm |

Laser wavelength | 1064nm |

Pulse width | ≤20ms |

Maximum laser power | 200W /300W / 400W/600W |

Pulse frequency | ≤100Hz |

Laser output focus length | 150mm |

Laser cooling | Water cooling |

Observing system | Microscope (360° adjustable) |

Protection gas | One line (xenon) |

Welding wire diameter | 0.1mm-2.0mm |